Frost & Sullivan

Recognizes Haber

for Innovation

in Industrial AI

Solutions That Think Ahead

Intelligence that powers better outcomes — from shop floor to top floor

0MW

Energy Saved

0Tons

Emissions Reduced

0m³

Water Saved

We Help You Master

What Matters The Most

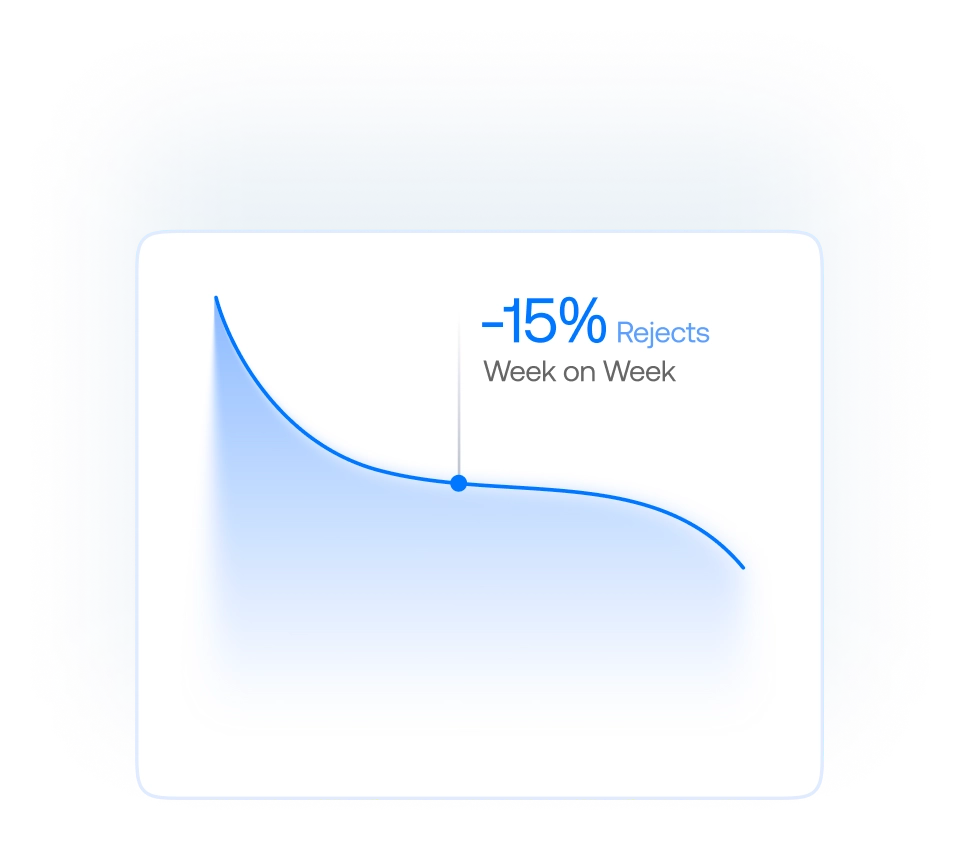

Achieve consistent, high-quality output through AI-driven monitoring, predictive control, and precision adjustments across every production run.

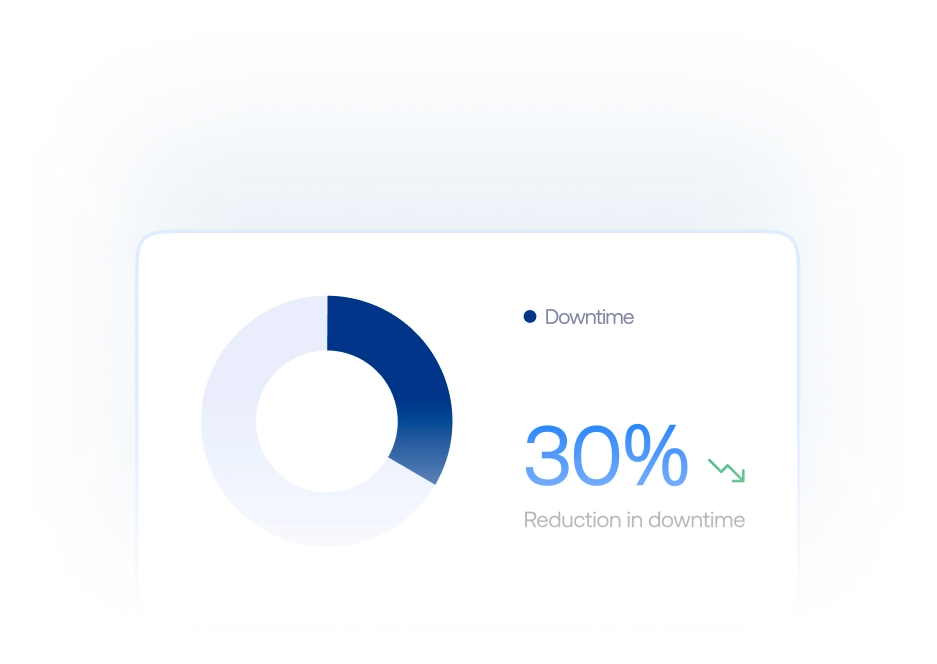

Optimize performance and uptime with intelligent insights that streamline operations, reduce bottlenecks, and boost throughput across processes.

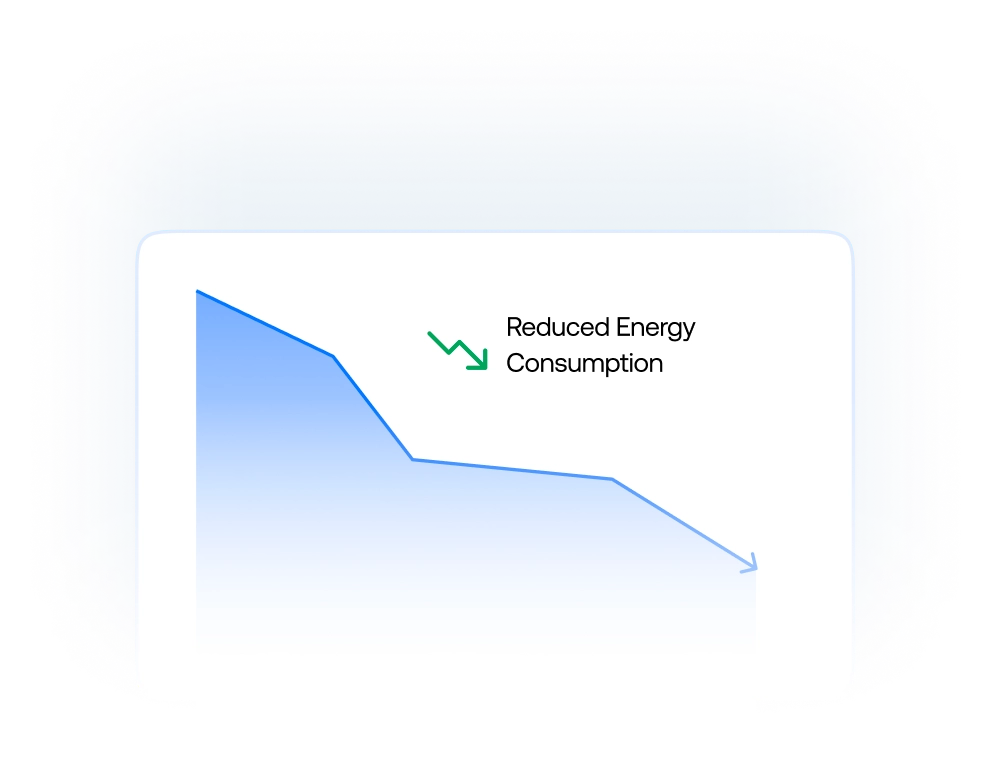

Cut chemical, water, and energy losses using real-time optimization and closed-loop control to drive sustainable cost savings.

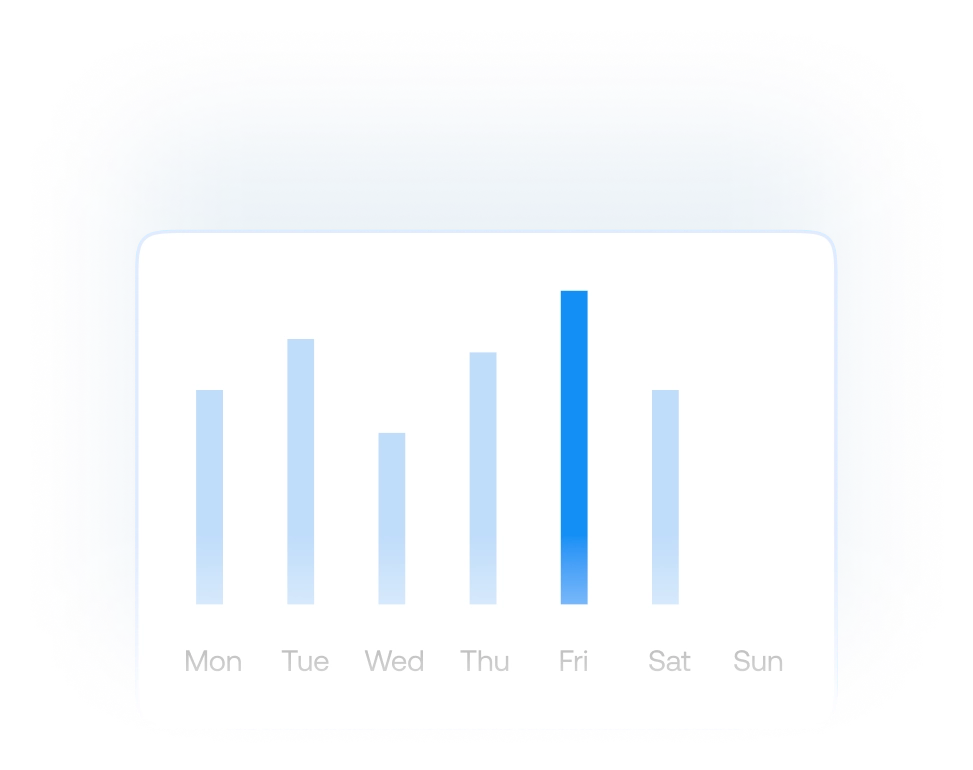

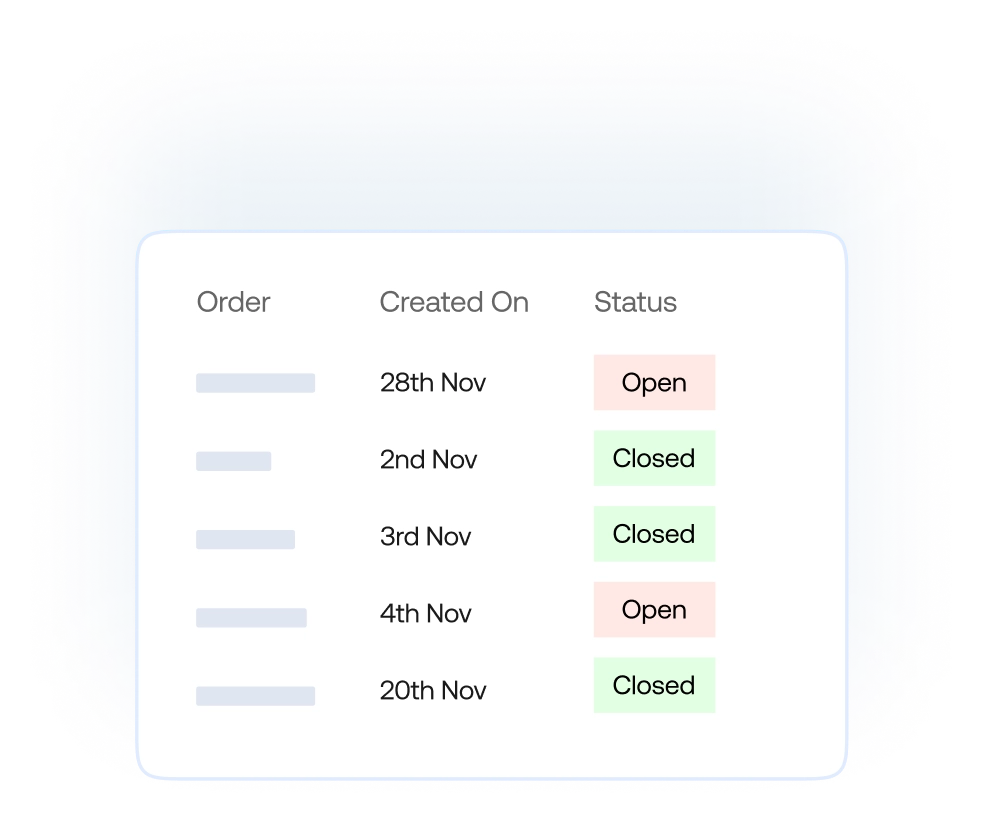

Balance demand, capacity, and materials through AI-powered production planning that minimizes trim loss and maximizes order fulfillment.

THE HABER EDGE

Your Partner for Intelligent Operation

From insight to action, we help you lead the way

INDUSTRIES

Innovation for Every Industry

Solutions that meet the unique demands of your industryCASE STUDIES

Real Results,

Proven Impact

CASE STUDIES

Real Results,

Proven Impact

TESTIMONIALS