Smarter Planning

and Seamless

Execution with

Kaiznn

Run lean, deliver fast, and delight customers with Kaiznn, which reduces waste, improves planning accuracy, and strengthens delivery performance.

Explore Kaiznn: Planning Made Faster and Smarter

Maximize Fulfillment

Maximize Fulfillment

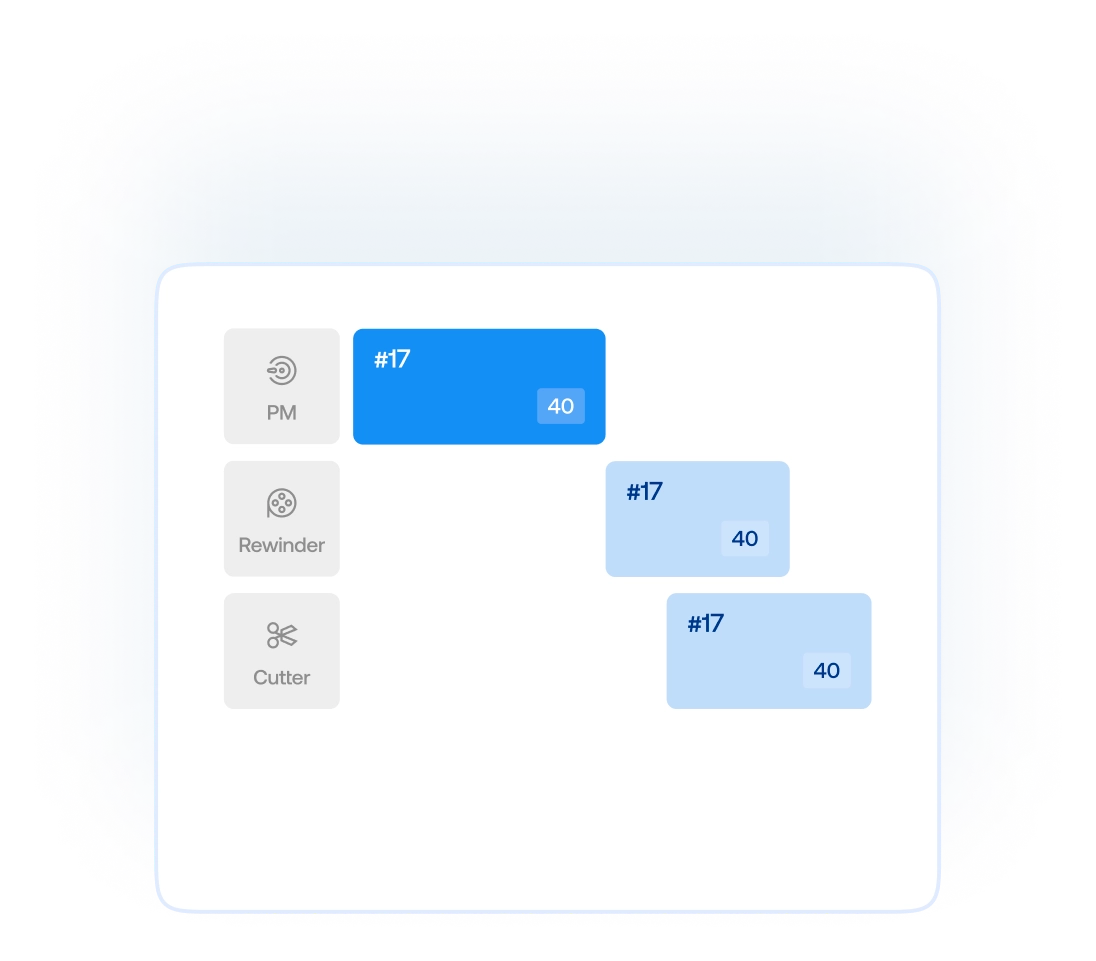

Schedule in Real-time

Schedule in Real-time

Optimize Production

Optimize Production

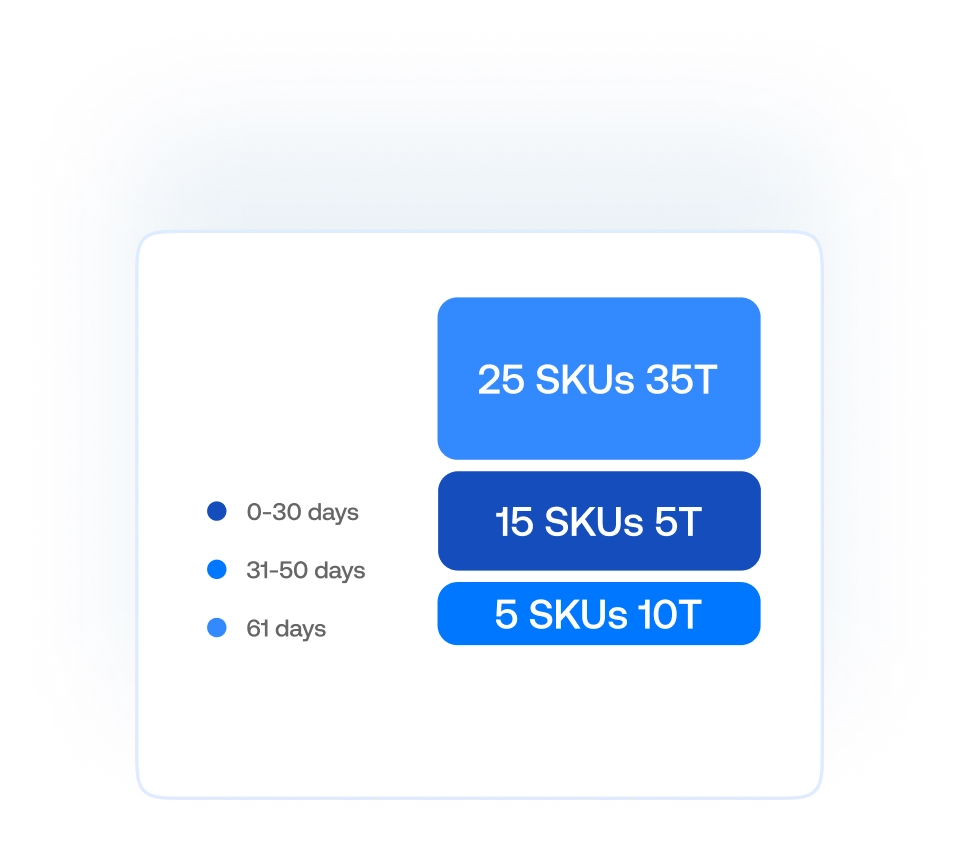

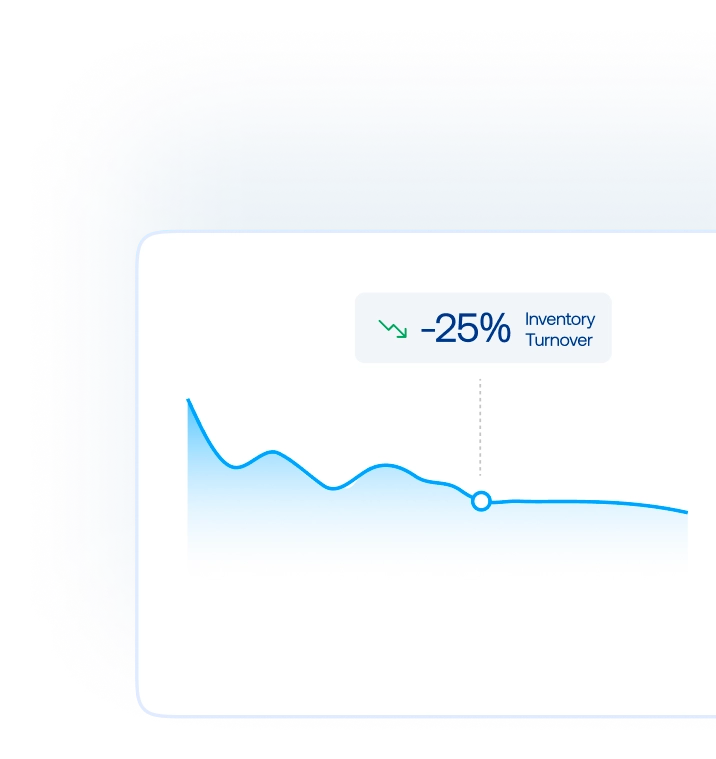

Manage Inventory

Manage Inventory

22%

on-time order fulfillment

7%

production waste

12%

changeover time

>20%

productivity increase

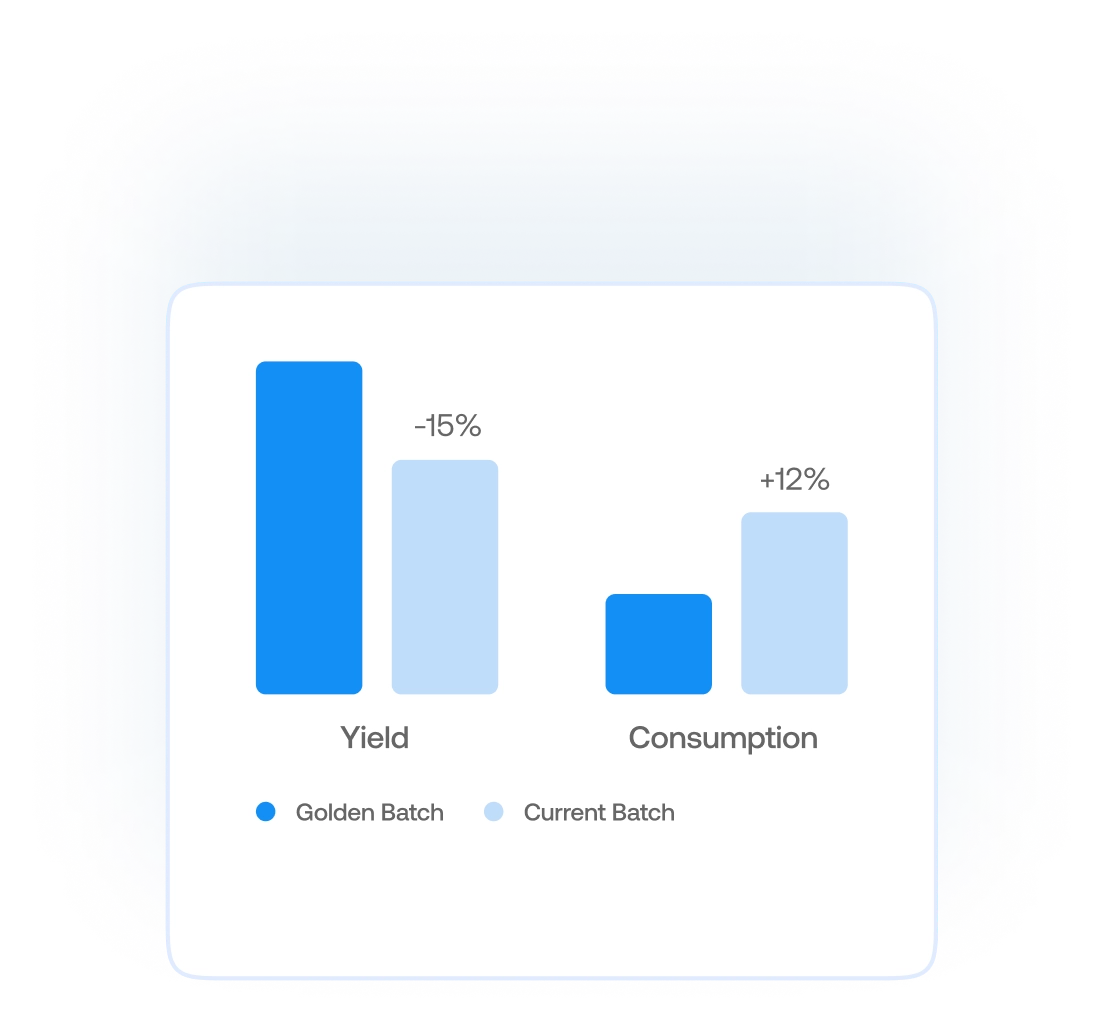

Up to 5%

decrease in trim loss

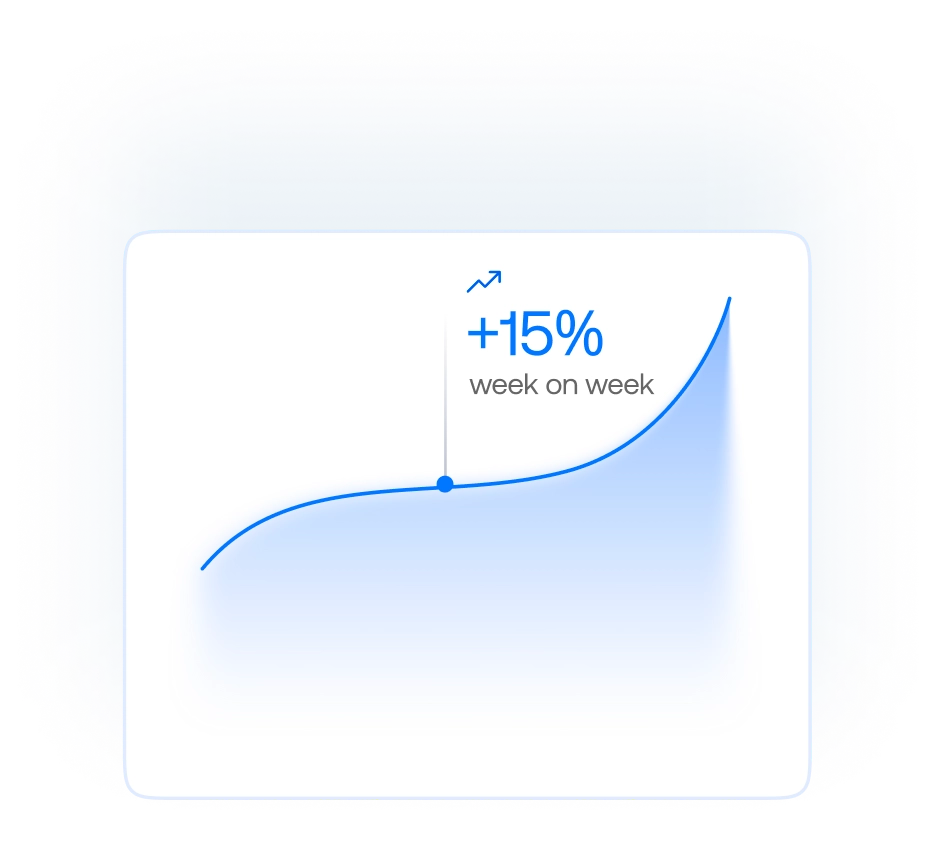

Up to 15%

increase in on-time order dispatch

zero disruption to production

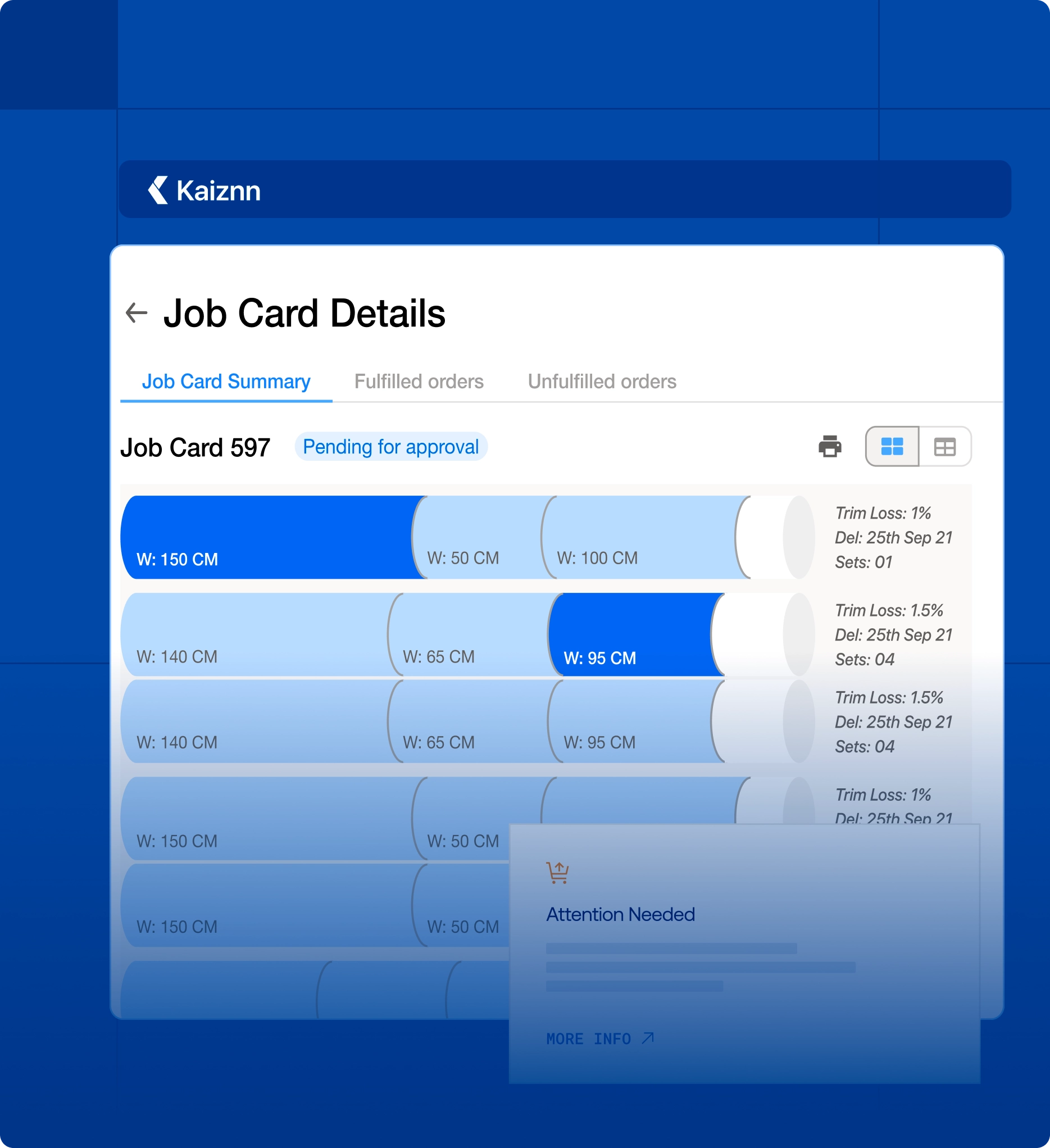

Intelligent Deckle Management with Kaiznn

Kaiznn for everyone

Obtain immediate deckle-match solutions, trim-loss calculations, and finalized solutions across grades, GSM, and customer requirements.

Achieve enterprise-wide visibility into order fulfillment, inventory levels, and deckle performance.

Achieve enterprise-wide visibility of order fulfillment, inventory levels, and deckle performance.

Kaiznn securely bridges IT and OT environments by integrating with MES, ERP, and inventory systems for unified planning.

Reduce the likelihood of stock buildup without compromising on delivery compliance.

CASE STUDIES

Real Results,

Proven Impact

CASE STUDIES

Real Results,

Proven Impact

TESTIMONIALS